Lint, Hair, Plaster & Starch Separators

|

Lint & Plaster Separators

Specification

Stainless Steel trap sized to suit laundry outflow. This contains a removable Stainless Steel mesh baffle designed to stop fibres from the washing programme entering the drainage system. Available in above and below ground units.

We advise customers to check quantities of detergent used in the laundry programme to ensure minimum discharge of the chemical is achieved. The liquid products used in the dry cleaning process should not enter a drainage system unless approved by water companies and the environment agency. |

| Lint / Plaster PL2 |

| Capacity Ltrs |

Inlet |

Outlet |

| 115 |

50mm |

50mm |

|

|

|

|

|

|

|

|

| Lint / Plaster PL3 |

| Capacity Ltrs |

Inlet |

Outlet |

| 191 |

50mm |

50mm |

|

|

|

|

|

|

|

|

|

|

|

| Lint & Hair Separators |

|

|

|

| Lint, Hair LHS3 |

| Capacity Ltrs |

Inlet |

Outlet |

| 288 |

110mm |

160mm |

|

|

|

|

|

|

|

| Lint, Hair LHS4 |

| Capacity Ltrs |

Inlet |

Outlet |

| 748 |

110mm |

110mm |

|

|

|

|

|

|

|

|

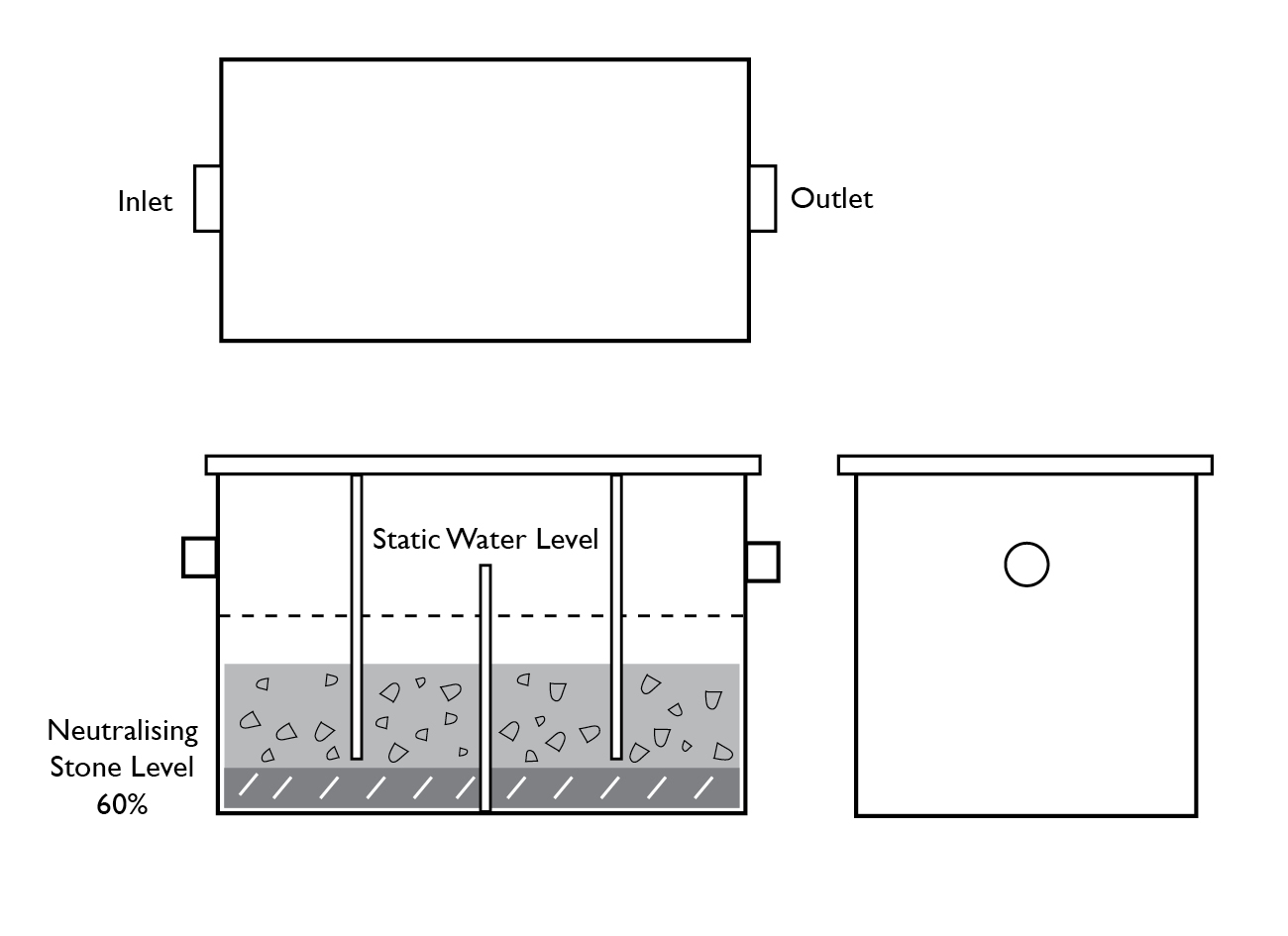

Neutralising Tank

|

- Under Ground Installation.

- Typically used in laboratories and metalwork or art/craft workshops.

- These tanks have three baffles and must be partially filled with neutralising stones. The baffle arrangement forces the liquid passing through the tank to filter through the neutralising stones, which have the effect of neutralising the water pH balances.

- Manufactured from 316-2mm Stainless Steel, the tank is suitable for underground installations.

- Inlet and outlet pipes are 110mm NS unless otherwise specified.

- The tank dimensions and pipe work positions are nominal and in all cases conform to NS recommendations.

- When space is limited, equivalent capacity tanks can be manufactured to order.

- Medium duty lid – Mild Steel Galvanised Durbar. Pedestrian lid – Aluminium – Durbar.

|

|

|

| Model |

Capacity Ltrs |

Lid W |

Lid L |

L |

H |

W |

Pipe

Connection |

| NT3 |

200 |

689mm |

1027mm |

940mm |

900mm |

602mm |

395mm |

| NT4 |

650 |

965mm |

1372mm |

1285mm |

1086mm |

878mm |

581mm |

| NT5 |

900 |

1050mm |

1550mm |

1463mm |

1160mm |

963mm |

655mm |

| NT6 |

1370 |

1150mm |

1720mm |

1633mm |

1300mm |

1063mm |

795mm |

|

Starch Separators

Specification

Prevents and treats the problems created by the production of waste starch in food process establishments. Fitted directly into the existing drainage system, the unit removes the cement like residue from blocking drainage pipes and sewer systems. Physical and biological treatment eliminates the need to constantly replace blocked sections of waste pipes due to the damage created from the residual starch waste.

Fitted with a unique Shower System to prevent build up of foam within the separators produced when a peeler is in operation. The Shower System is fitted with an electronic valve which allows water to flow through the Shower System when the potato peeling process is in operation. An extra large removable basket is fitted in the trap to collect food solids (e.g potato peelings etc.)

| Starch SS0501 |

Capacity

Ltrs |

Inlet |

Outlet |

| 57 |

50mm |

50mm |

|

|

|

|

|

|

| Starch SS0502 |

Capacity

Ltrs |

Inlet |

Outlet |

| 96 |

50mm |

50mm |

|

|

|

|

|

|

|

|

|

| Starch 0L56 |

| Capacity Ltrs |

Inlet |

Outlet |

| 1600 |

110mm |

160mm |

|

|

|

|

|

|

|

|

| The Aluline Dosing System and Aeration is included with this model. |

|

|

|

|

Electronic Valve Specification

|

| Supple Voltage |

240v AC 50Hz |

| Power Consumption |

6 Watts |

| Operating Temperature Range |

+5 - +88°C |

| Cable Length |

1 Metre |

| Maximum Differential Pressure |

1 Bar |

| Maximum Static Pressure |

10.0 Bar |

| Maximum Fluid Temperature |

100°C |

| Maximum Ambient Temperature |

52°C |

|

| Contact Aluline for FREE comprehensive operating instructions and advice. |

To Order Tel: 01928 563532  |

|

|

|

|

|