|

Sizing Biological Grease Separators

In accordance with current guidance from Water Authorities, dishwashers and waste disposal units should not be connected to grease separators.

Sizing AG Series

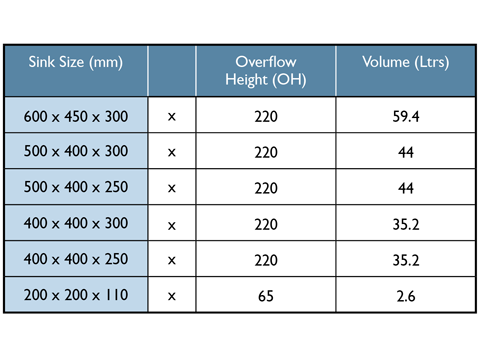

Please refer to the chart on the relevant page for the grease trap sizes.

To determine the size of grease trap, calculate the volume of water, divide by the discharge time (2 minutes).

Example:

Sink Size

2 x 400 x 400 x (250), overflow height (OH) is 220. Volume is 2 x 400 x 400 x 220 = 70.4L

Sink Size

l x 500 x 400 x (300), overflow height (OH) is 220. Volume is 31 x 500 x 400 x 220 = 44.0L

Total Volume = 114.40L

Size of Grease Trap

114.4L divided by discharge time (2 Min) = 57.2L

Use AG2 (115L) for Above Ground Series.

L cubic m = 1 tonne -1000L

The calculation of Grease/Oil Interceptor size is not an exact science, factors to account for are: type of premises, cleaning regime, staff training, frequency of cleaning, available space for fitting, place of trap eg: above floor/below floor inside kitchen-outside kitchen. Supplier should have experience to advise on trap sizing, training & cleaning frequency.

|

|

The actual loading should be assumed to be 60% of the above value, as most appliances and fixtures are not filled to the brim. In many cases, these fixtures are filled to less than 60% of the capacity, especially when water is at premium. Most large businesses reduce water consumption to attain economic and environmental benefits and reduce carbon footprint.

Sizing UG Series

We use the same methodology for the Under Ground series (however as a rule of thumb) we advise using one size larger to reduce the cleaning regime.

When specifying Under Ground Traps, the T-Dimension or invert level, it is important to ensure that the lid is at a finished level and increment cost can be calculated for bill of quantities.

Access to final position for cleaning is important during the specification stage.

Flow Rating

A 2 minute drainage period is acceptable for commercial fittings to fully discharge. To calculate the flow rating, simply divide the litre capacity of the kitchen fixtures and equipment by 2 (drainage period) to give flow rating in litres/minute then divide by 60 to calculate litres/second.

Example

59.4 litres multiplied by 0.60 to give actual loading for a single catering sink = 35.64 litres. This is then divided by 2 = 17.83 litres per minute or 0.297 litre per second.

Under European Legislation, dishwashers are assumed to have flow rating 2 litres/second.

|